-

The introduction of E-Procurement.

The introduction of E-Procurement:

Price and availability are not the only factors to be considered in a purchasing decision, especially now that a robust supply chain has become an unmissable element for every company in today’s business climate. The supply chain sector is always changing and adapting and business owners must be able to keep up and adapt as needed. Improved digitization and automation within e-business and e-commerce is a leading option.

Managing the complex web of advantage logistics and supply chain operations is both complicated and streamlined by e-commerce trends. It is important that those doing business online understand the connection and relationship these two sides of the same coin share.

The dynamic of business worldwide is changing rapidly due to fast-growing technological advancements. The ease of accessibility of this technology causes many organizations to shift towards E-Procurement as an effective and strong supply chain support system.

Innovative processes and systems like this can help companies reach operational efficiencies, sustainability, and profitability goals. All online businesses must keep a sharp eye on logistics and purchasing trends. This is true whether a business is looking for where to get products to sell on Shopify or any other finer details involved with e-commerce management.

Using E-Procurement for Advantage Logistics Management

The use of E-Procurement has recently increased as technologies positively affect different sectors worldwide. E-procurement, known as ‘electronic procurement’ or ‘supplier exchange’, is changing how companies are sourcing their goods and services.

Advantage logistics and an omnichannel supply chain help managers and business owners improve procurement online and simplified business processes. According to (Namulo, 2017), “E-Procurement is the acquisition of goods, services or works from an external source. In procurement, it is necessary to ensure that the goods, services, or works are appropriate and that they are procured at the best possible cost to meet the purchaser’s needs in terms of quality, quantity, time, and location.”

Over the last ten years, institutions have used more electronic tools to manage their procurement activities. Organizations in both public and private sectors are adopting systems such as the Electronic Data Interchange tool (EDI), Enterprise Resource Planning (ERP), and of course, the internet to benefit them when sourcing their goods (Adebayo, Dec 2015).

Advantages/Disadvantages of E-Procurement

E-procurement is a tool that yields benefits in all kinds of ways. It enables companies to decentralize operational processes and centralize strategic procurement processes. This approach to advantage logistics results in higher transparency and integrity, as well as reducing transaction cost and boosting decision-making processes.

E-procurement enables price negotiation and supplier evaluation. It also allows selection to be automated between organizations and their suppliers, which prevents time consumption. It helps reduce human errors, increase operational speed and enable staff to focus on other tasks.

Moreover, e-procurement enables companies to have a good workflow that facilitates end-users self-services. The inflows/outflows of goods through the supply chain improves as the tracing and tracking of those goods are automated, reducing emergency shipments.

Institutions can visualize their purchasing behaviors to control purchasing management and save costs by identifying leverage buying power (digital, n.d.). Being connected to external supply chains and enterprise resource planning (ERP) enables companies to get a better overview of supplier transactions and information by sharing real-time data through ERP systems, improving communication (digital, n.d.).

It is important to note that there are also obstructing factors that prevent implementing effective procurement for some e-commerce businesses. Lack of strong business relationships, financial support, and organizational priorities can also form obstacles. Developing countries are usually late adopters and do not invest money into early adopters’ trends and often struggle with advantage logistics and more complex supply chain and online business logistics within the global supply chain

Concept of Implementing E-procurement in Online Stores and Businesses

Electronic procurement innovations (EPIs) are being utilized by many businesses to improve their supply chain and advantage logistic processes. EPIs support the different parts of businesses’ core procurement process, such as supplier selection, order placement, order fulfillment, supply chain tools usage, payment settlement and ecommerce fraud protection.

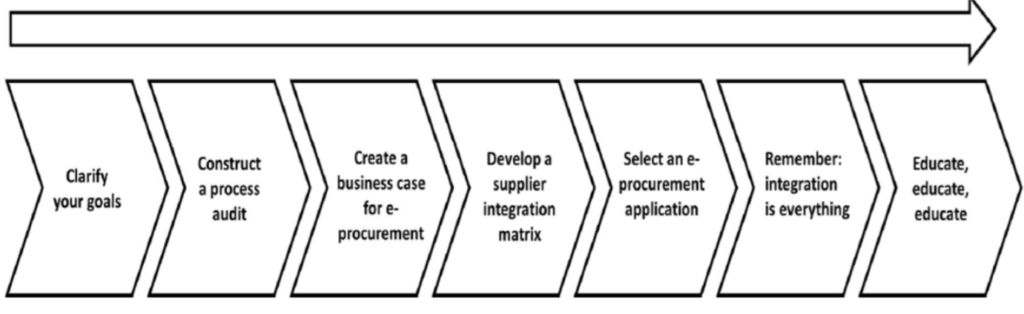

Many organizations use the scheme below to help implement e-procurement into their supply chain (Namulo, 2017). Successful implementation of e-procurement depends on strong good management to achieve the firm’s performance goals and to maintain high levels of customer service. This makes it easier to target audience groups and use internet technology to sell products and services more efficiently.

It is essential to be aware of what adopting e-procurement means on a long-term and short-term basis. E-procurement has become a powerful tool resulting in a competitive advantage for many businesses. It is integrated into many firms’ overall strategies as the role of IT has evolved from productivity to a strategic tool (KANDA, 2017).

(Namulo, 2017).

Five Forms of E-Procurement to Know:

Understanding the inner workings of e-commerce, e-procurement, and e-business operations can help owners and managers in the short and long term. E-commerce fraud protection and other vital processes are easier when team members know what to expect along the way.

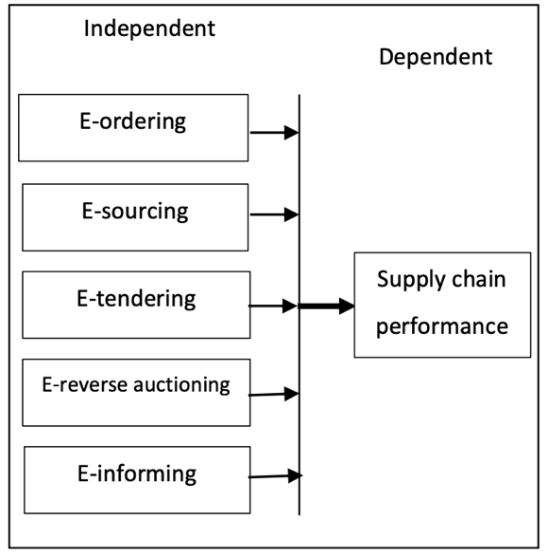

Supply and demand cycles and consumer buying habits have been altered by the COVID-19 pandemic and businesses must shift focus to compensate. An electronic procurement system can be categorized into five main applications within advantage logistics, which consist of E-ordering, E-sourcing, E-tendering, E-auctioning, and E-informing.

- E-ordering: is a popular option. Based on (Zaman, 2019), E-ordering captures electronic data, including orders, requests, and information received by the customer. From the supplier’s side, E-ordering can reduce errors and eliminate papers as invoices are automatically generated from the order information through the internet (Edicom, 2020).

- E-sourcing is described as selecting and identifying suppliers based on specific requirements. This approach allows the firms to choose their preferred suppliers considering their competitive aspects.

- E-tendering is when the suppliers receive the invoices and the purchase requests. This process allows both suppliers and buyers to realize their online transactions. Moreover, the procedure covers the tender requirements, which will be exchanged electronically through the CRM platforms (Zaman, 2019).

- E-auctioning: Online reverse Auctions facilitate the buyer’s ability to select suitable suppliers to buy products or services. Instead of negotiating with several suppliers before choosing one, this process helps with reducing the cost of contact and providing feedback and privacy (Namulo, 2017).

- E-informing: This method includes assembling and gathering information regarding purchases of buyers and suppliers by using web-based technology (Zaman, 2019). It leverages the power of digital platforms and data-sharing systems to strengthen businesses.

The supply chain performance is dependent on each of the stated independent e-procurement steps. These steps aim to improve the overall supply chain performance. (Zaman, 2019).

Master E-Procurement Processes Today With Help From Industry Leaders

The supply chain performance is dependent on each of the stated independent e-procurement steps. These steps aim to improve the overall supply chain performance. Would you like to know more about adopting E-Procurement within your supply chain? Contact one of ModusLink’s Industry experts today to get started with advantage logistics.

Bibliography:

Adebayo, V. &. (Dec 2015). Adoption of e-Procurement Systems in Developing Countries: A Nigerian Public Sector Perspective. In V. &. Adebayo, 2015 2nd International Conference on Knowledge-Based Engineering and Innovation (KBEI) (Vols. pp. 20-25, pp. 20-25). Tehran, Iran: IEEE.

Cheney, C. (2020, July 01). How COVID-19 has advanced the case for procurement reform. Retrieved from Devex.com. demery, P. (n.d.). Digital commerce 360 . Retrieved from digitalcommerce360.com.

digital, W. (n.d.). What is e-procurement . Retrieved from Waxdigital.com.

Edicom. (2020, March 12). What Are Electronic Orders? Benefits and Success Cases in Europe.Retrieved March 2020, from Edicomgroup.com.

KANDA, V. I. (2017, April). Factors Affecting the Adoption of e-Procurement Systems among

International Non-Governmental Organisations in Kenya. International Journal of Academic Research in Accounting, Finance and Management Sciences, 7(2), 164-176.

Kapepo, S. K. (2019, July ). The Role of Institutional Pressures in the Adoption of e-Procurement

in Public Institutions in Developing Countries: The Case of Lesotho. The African journal of information systems, 11(3 ), 232-248.

Mwangi, E. W. (2016, August 19). EFFECTS OF E-PROCUREMENT ON PROCUREMENT

PERFORMANCE IN HOSPITALITY INDUSTRY IN KENYA: CASE OF SAROVA CHAIN OF HOTELS. International Academic Journal of Procurement and Supply Chain Management, 2(2), 1-19.

Namulo, M. M. (2017, August). Employee Adoption of E-Procurement and its Implication on Supply Chain in Developing Countries. International Journal of Computer Applications , 171(9), 11-15.

NGUI, A. M. (October 2016). BARRIERS TO E-PROCUREMENT ADOPTION BY SMALL AND MEDIUM ENTERPRISES IN MACHAKOS COUNTY. reserach paper, UNIVERSITY OF NAIROBI, SCHOOL OF COMPUTING AND INFORMATICS, Nairobi.

Oracle. (n.d.). What is ERP . Retrieved from Oracle.com – Malaysian Manufacturing Firm. International journal of supply chain management, 8(2), 923-929.

-

Sustainable Supply Chain Management.

Green supply chain history:

The origin of Supply Chain Management and modern supply chain history dates back to the early 20th century with Henry Ford, who vertically integrated the automotive supply chain and organizational practices. The approach of “Just in time” and “supply chain management” focused on optimizing efficiency and reducing waste- including water pollution, noise pollution, air pollution, and more. The impact these waste products have on human health, as well as the environment, is becoming increasingly important for consumers.

Nowadays, many factors are increasing the urgency for emerging economies to become sustainable. The shifting consumer focus and changing market demands mean more and more high paying logistics jobs are available and these niche services are increasingly needed. Digitization and automation go hand in hand with increased productivity and sustainability today.

A great example would be climate change and how that has affected the overall shift in supply chain operations from improved fuel conservation to stronger 3PL partnerships and the increasing popularity of google warehouse and third-party options. The struggle to contend with environmental pollution concerns is becoming more vital than ever before among businesses of all sizes and across all industries and markets.

Why Go Green- What 3PL Reports Show

Due to climate change, firms are rethinking their strategies to guarantee environmental initiatives to start ecological actions. Furthermore, the notion of Sustainable Supply Chain Management is often linked with social responsibility or environmental management (Ali Esfahbodi, 2016).

Green Supply Chain Management (GSCM) emerged as a new environmental approach in logistics and has been increasingly used by forward-thinking organizations. Many companies today are looking for ways to save time and money, which is why services such as google warehouse operations and other 3PL relationships are becoming more popular than ever.

Different reasons to turn to GSCM include strong benefits of sustainable, profitable, and cost reducing operations. Customers usually say that they would instead buy products that are environmentally friendly and with a minimum of environmental impact.

Business practices ought to become increasingly transparent; therefore, the green policy can generate profits, provide a positive social impact, and reduce environmental impacts. Shifting away from fossil fuels to more sustainable options is a key part of modern supply chain engineering and logistical management.

Any steps taken to become greener within e-commerce solutions will favor companies in visibility, and credibility, and develop a leadership reputation (Bhattacharjee, 2015). Implementing more sustainable practices, shifting to greener modes of transport, and improving fuel consumption and truck routing processes can have a significant impact on the supply chain today.

Sustainable Supply Chains and Google Warehouse Management

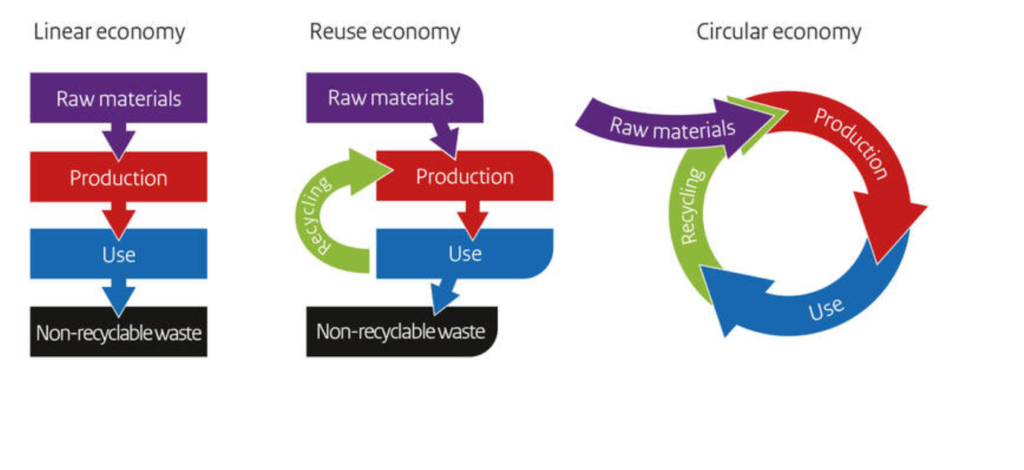

The original model of Supply Chain Management follows a linear production that hypothesizes the constant input of natural resources and an unlimited capacity to assimilate waste. Unlike the traditional supply chain, being sustainable considers the environmental impact of a product through its entire process cycle and reduces maximum environmental damages.

The idea of being sustainable is done by closing the loop and including the reduction, reuse, and recycling processes. This will alter the environmental impact of e-commerce lines from acquiring raw materials to the final use and disposal of the product (Ali Esfahbodi, 2016).

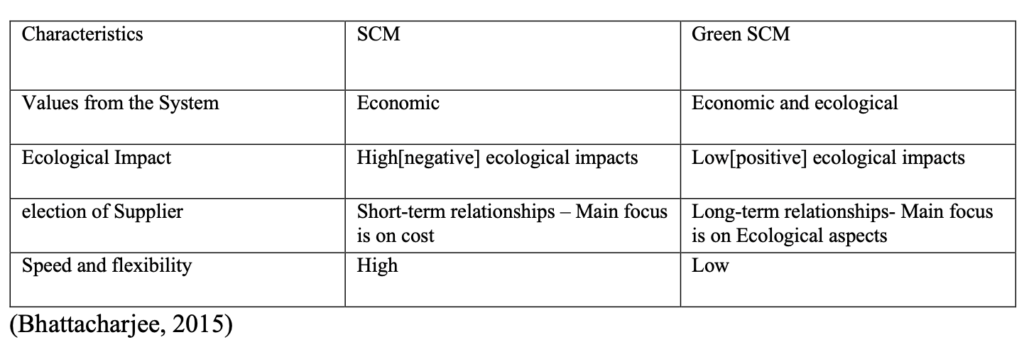

The purpose of going green is shown in the table.

Sustainable supply chain management:

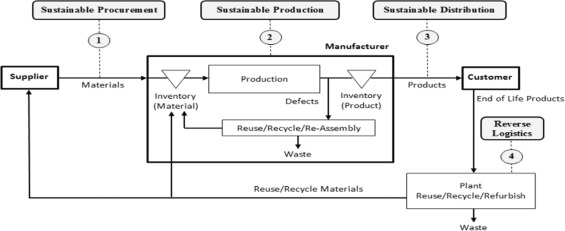

The original model of Supply Chain Management follows a linear production that hypothesizes the constant input of natural resources and an unlimited capacity to assimilate waste. Unlike the traditional supply chain, being sustainable considers the environmental impact of a product through its entire process cycle and reduces maximum environmental damages. The idea of being sustainable is done by closing the loop and including the reuse, recycle step. This will aim at reducing environmental impact from the acquisition of raw materials to the final use and disposal of the product (Ali Esfahbodi, 2016).

Based on (Ali Esfahbodi, 2016), the main activities in a typical sustainable supply chain management (SSCM) are illustrated above. When the product has a defect after its production, it is sent back to the inventory to reuse or recycle it. When the product comes to its end, it goes to the plant where the product is reused, recycled, or refurbish before heading back to the supplier.

Four fundamental practices:

Understanding the way traditional vs e-business models impact sustainability is a vital step to the optimization of the supply chain. Based on (Ali Esfahbodi, 2016) research, Chinese and Iranian governments have focused their fight for GSCM based on four fundamental practices: sustainable procurement, sustainable production, sustainable distribution, accurate 3PL reporting, and reverse logistics.

These practices represent how each country engages itself toward Sustainable Supply Chain Management. In addition, these initiatives are not just used in China and Iran but also in many other emerging economies. These innovations represent a substantial commitment through strategic environmental plans toward sustainable Supply Chain Management.

Sustainable Procurement

consists of environmentally friendly purchasing that carries reduction, reuse, and recycling options. Furthermore, it is a solution to achieve a selection of products and services that reduce the negative impact of the life cycle.

Sustainable purchases become easier throughout the year with fewer barriers as customers increase their demands for environmentally friendly goods (Vishal Gupta, 2013). Ikea is a good example as it has sourced close to 50 percent of its wood from sustainable foresters and a hundred percent of its cotton from farms that meet better cotton standards (Ikea, n.d.).

Sustainable Production

Is the production process that uses inputs with low environmental impact, is greatly influential, and causes no waste pollution. Green production can improve the corporate image and lower the raw material cost.

Companies are starting to take action and produce materials that intend to be reliable, and energy-efficient with no or lesser waste. This benefits companies in many ways as it will impact customers, shareholders, and the company’s recognition in the e-commerce marketplace. (Vishal Gupta, 2013).

Sustainable Distribution

The distribution of goods usually generates a lot of waste and it can damage the environment, but green distribution consists of green packaging including size, shape, and materials that have an impact on the transportation of the goods.

Better packaging can reduce material usage, increase space utilization in the warehouse and trailer, and lower the quantity of handling required (Vishal Gupta, 2013). Logistrap does it in Mexico, they reduced their space within the warehouses and container ships to transport more within the same number of trips (Logistrap, 2020).

Reverse Logistics

According to (Vishal Gupta, 2013) the concept of Reverse Logistics (RL) means the returns from not only the customers but also the management of E-waste. RL is a process where a manufacturer accepts previously shipped products from the customer’s point of view for potential recycling and/or re-manufacturing.

Partnerships such as google warehouses and 3PL service providers can improve reverse logistics and keep the supply chain flowing smoothly with enhanced supply chain tools and tech. Backward integration and monitoring are necessary, especially during peak seasons when purchases, as well as returns, can be higher than normal.

Improve 3PLS Reports and Logistics Management With ModusLink

Do you need help figuring out how to become more sustainable within your management and logistics operations? Mastering the flow of 3PL reports, google warehouse management, and other supply chain management operations is a vital part of modern business operations today. Contact one of ModusLink’s leading supply chain management and logistics experts.

Bibliography:

12 Million Bottles Used in Patagonia Recycled Clothes. (1995, April 12). Los Angeles Times. Ali Esfahbodi, Y. Z. (2016). International journal of production economics (Vol. 181 part B). (S.Minner, Ed.) Birmingham , UK: Elsevier.

Avittathur, A. A. (2016). Green Retailing: A New Paradigm in Supply Chain Management.

Calcutta, India: IGI Global.

Bhattacharjee, K. (2015). Green Supply Chain Management- Challenges and Opportunities.

Research scholar, Patna University, Applied economics & Commerce, Patna. Cardwell, D. (2014, July 30).

At Patagonia, the bottom line includes the earth. The New York Times(section B), 1.

CHAPPELOW, J. (2016, March 16). Emerging market economy. Retrieved from Investopedia. consulting, T. E. (n.d.). reverse logistics in a circular economy. Retrieved from Triple EFFconsulting.

EM Ojo, C. M. (n.d.). GREEN SUPPLY CHAIN MANAGEMENT IN DEVELOPING COUNTRIES. In C.

M. EM Ojo. Johannesburg, South Africa : Department of Mechanical Engineering Science, University Of Johannesburg, Johannesburg, South Africa. Ikea. (n.d.). Corporate news. Retrieved from Ikea.com.

Kobo360. (n.d.). Kobo. Retrieved from Kobo360.com.Logistrap. (2020). Logistrap packing services. Retrieved from Logistrap.com. 15

Mohsin Malik, S. A. (2019). Sustainability Initiatives in Emerging Economies: A Socio-Cultural Perspective . Swinburne University of Technology. / Abu Dhabi University., Department of Business Technology and Entrepreneurship / College of Business Administration. Abu Dhabi, UAE.: MDPI.

O. Zhu, J. S. (2005). Green supply chain management in china: pressures, practices and performance (Vol. 5).

Queiroz, M. M. (2019). Environmental Quality Management (Vol. 3). (Wiley, Ed.) Wiley.

Rama K. Jayanti, M. R. (2014). Sustainability dilemmas in emergingeconomies. (I. M. review, Ed.)Bangalore, India: Elsevier Ltd.8).

Vishal Gupta, N. A. (2013, January). Green Supply Chain Management Initiatives by IT

Companies in India. The IUP Journal of Operation Management , 12(2), 6-24.

-

The Circular Economy.

The Circular Economy

Taking the fastest route towards your destination is often the most effective one as you will use the least time possible. However, is it also the most efficient? This is a completely different question. Your efficiency depends on how you determine your efficiency factor. Is your idea of efficiency to spend the least amount of money on fuel? To take the route in the most sustainable way possible? To see the most beautiful scenery along the way? If your idea of efficiency is one of these mentioned, your strategy of taking the fastest route is probably not a good idea. This concept of efficiency is crucial for businesses to understand as it allows them to optimize their operational activities and business model.

Businesses often conduct their operations as streamlined as possible with the integration of supply chain tools, omni logistics, e-commerce practices, and sustainable processes. To improve payment processing, customer service, logistics management, and to have a strong supply chain, it will take strong commitment and focus. Let’s take an average supply chain from a start-up.

Supply Chain Processes and the Circular Economy

Understanding the processes used by businesses of all sizes is critical for supply chain operations today. Everything from logistics company names to reputation and internal processes need to be considered.

First, the sought-after raw materials are procured. Then, the business uses these raw materials and labor to convert them into their final product. Lastly, this product is sold, and any waste material is disposed of.

This Linear way of conducting business is often how many start-ups begin their journey as it seems practical and straightforward. Depending on your business model/goals, there might be an alternative way to conduct business that yields benefits such as increased resource utilization, labor force efficiency, and sustainability within your business model.

The circular economy is a term used within Business practices that primarily aims to reinforce sustainability within business elements (Ministerie van Infrastructuur en Waterstaat, 2019). It is a great piece of the subscription management solution and customer subscription management. It is a foundational process.

The fundamental pillars of a circular economy are made of the term reusability. Instead of disposing of waste, waste materials are used through methods such as recycling, aiming to give purpose to waste.

During the end-to-end creation of glass but can be utilized more effectively. This residue is melted in a circular economy to create new glass. It is a circular process that feeds from one into the other and saves time, money, resources, and labor..

Integration of Subscription Management Solutions and Omni Logistics

There are many Supply Chain elements where the Circular Economy concept can be integrated. These elements include the following.

- Product design

Fundamentally altering product design can yield strong sustainability benefits. This is often best done when releasing/starting a new product, as big changes could take time to implement on scale. Sustainable packaging and product labelling is a way to integrate the Circular Supply Chain concept. The razor blade company ‘Boldking’ for instance gives their customers discounts on future products when sending back their packaging. The used packaging is later converted into new razor blade packages.

- Procurement

Raw materials that are technically restorative or intrinsically reusable have a low negative environmental impact thus increasing sustainability within Supply Chains. The concept of acquiring such materials is often called ‘Green Procurement’.

These materials increase the utilization rate and decrease waste generation. Examples are glass and paper as mentioned earlier and there are many other examples of subscription management solutions and sustainable processes that are in high demand today.

- Production

Sustainable manufacturing practices are a great way to maintain a Circular Supply Chain. Although green production hasn’t been widely used (mostly due to cost-benefit compared to cheap labor), it certainly yields strong benefits when implemented correctly.

Producing using renewable energy sources such as Solar Power reinforces an autonomous production process. It is also a key component of omni logistics and supply chain operations.

- Logistics

Sustainably distributing products can be achieved through route optimization and avoiding concepts such as same-day delivery. It is important to be aware of your current logistical process. Consulting experts on the best way to distribute your products or manage your internal logistical process can be extremely beneficial as professional expertise can guide (in)experienced businesses in the right direction.

- Consumption

Consumption is an interesting way to apply Circular Supply Chain Management as it has not been used until recently. It is predominantly gaining traction within the mobile phone industry where unwanted phones are returned to the respective company in return for discounts on newer models. Since new phones are often released on an annual basis, this is a great way for companies to regain their resources.

- Waste Management

Waste management is essentially reusing waste material for your production process. To take the prior example, the unwanted and returned phones (waste) are not disposed of but instead taken apart carefully. Individual elements such as the processing unit, battery, Glass, metal frame, are all given a new purpose by reusing them in the new production process.

- Supply Chain Technology

The newest addition to integrating a Circular Supply Chain into a business is done through Sustainable Technology. This concept hasn’t been adopted on a wide scale as much technology is relatively new, however, some companies see the benefits gained from certain technology.

TTechniques and concepts such as IoT (Internet of Things) and omni logistics can yield substantial benefits when adopted correctly. If there is no inside knowledge on these concepts, it is strongly advised to seek professional expertise.

Bringing Circulate Economy Trends Together With Supply Chain Management

Circular Supply Chain Management (CSCM), integrates the philosophy of the circular economy into supply chain management. This creates a new and compelling perspective on the supply chain sustainability domain (Farooque et al., 2019).

Need professional advice on the right way to integrate circular supply chain management and sustainable subscription management solutions? Contact one of ModusLink’s Industry experts to get started!

Bibliography:

Angelis, D. R. (2018). [PDF] Supply chain management and the circular economy: towards the circular supply chain | Semantic Scholar. Semanticscholar.Org. https://www.semanticscholar.org/paper/Supply-chain-management-and-the-circular-economy%3A-Angelis-Howard/68c441507594095a7f07af8018c844194b88fa84

Farooque, M., Zhang, A., Thurer, M., Qu, T., & Huisingh, D. (2019, April 1). Circular supply chain management: A definition and structured literature review. ResearchGate. https://www.researchgate.net/publication/332690616_Circular_supply_chain_management_A_definition_and_structured_literature_review

Ministerie van Infrastructuur en Waterstaat. (2019, March 26). From a linear to a circular economy. Circular Economy | Government.Nl. https://www.government.nl/topics/circular-economy/from-a-linear-to-a-circular-economy

Supply chain management in the era of circular economy: the moderating effect of big data | Emerald Insight. (2020, September 3). Emerald.Com. https://www.emerald.com/insight/content/doi/10.1108/IJLM-03-2020-0119/full/html