Green supply chain history:

The origin of Supply Chain Management and modern supply chain history dates back to the early 20th century with Henry Ford, who vertically integrated the automotive supply chain and organizational practices. The approach of “Just in time” and “supply chain management” focused on optimizing efficiency and reducing waste- including water pollution, noise pollution, air pollution, and more. The impact these waste products have on human health, as well as the environment, is becoming increasingly important for consumers.

Nowadays, many factors are increasing the urgency for emerging economies to become sustainable. The shifting consumer focus and changing market demands mean more and more high paying logistics jobs are available and these niche services are increasingly needed. Digitization and automation go hand in hand with increased productivity and sustainability today.

A great example would be climate change and how that has affected the overall shift in supply chain operations from improved fuel conservation to stronger 3PL partnerships and the increasing popularity of google warehouse and third-party options. The struggle to contend with environmental pollution concerns is becoming more vital than ever before among businesses of all sizes and across all industries and markets.

Why Go Green- What 3PL Reports Show

Due to climate change, firms are rethinking their strategies to guarantee environmental initiatives to start ecological actions. Furthermore, the notion of Sustainable Supply Chain Management is often linked with social responsibility or environmental management (Ali Esfahbodi, 2016).

Green Supply Chain Management (GSCM) emerged as a new environmental approach in logistics and has been increasingly used by forward-thinking organizations. Many companies today are looking for ways to save time and money, which is why services such as google warehouse operations and other 3PL relationships are becoming more popular than ever.

Different reasons to turn to GSCM include strong benefits of sustainable, profitable, and cost reducing operations. Customers usually say that they would instead buy products that are environmentally friendly and with a minimum of environmental impact.

Business practices ought to become increasingly transparent; therefore, the green policy can generate profits, provide a positive social impact, and reduce environmental impacts. Shifting away from fossil fuels to more sustainable options is a key part of modern supply chain engineering and logistical management.

Any steps taken to become greener within e-commerce solutions will favor companies in visibility, and credibility, and develop a leadership reputation (Bhattacharjee, 2015). Implementing more sustainable practices, shifting to greener modes of transport, and improving fuel consumption and truck routing processes can have a significant impact on the supply chain today.

Sustainable Supply Chains and Google Warehouse Management

The original model of Supply Chain Management follows a linear production that hypothesizes the constant input of natural resources and an unlimited capacity to assimilate waste. Unlike the traditional supply chain, being sustainable considers the environmental impact of a product through its entire process cycle and reduces maximum environmental damages.

The idea of being sustainable is done by closing the loop and including the reduction, reuse, and recycling processes. This will alter the environmental impact of e-commerce lines from acquiring raw materials to the final use and disposal of the product (Ali Esfahbodi, 2016).

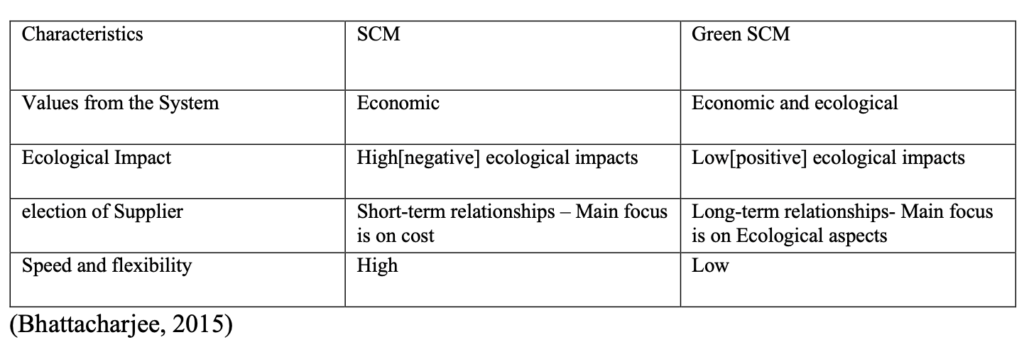

The purpose of going green is shown in the table.

Sustainable supply chain management:

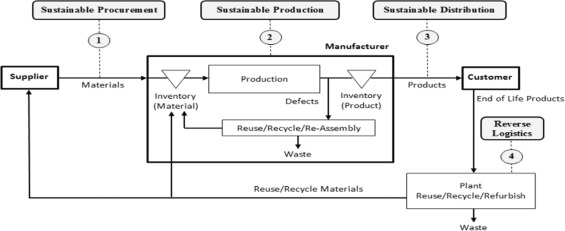

The original model of Supply Chain Management follows a linear production that hypothesizes the constant input of natural resources and an unlimited capacity to assimilate waste. Unlike the traditional supply chain, being sustainable considers the environmental impact of a product through its entire process cycle and reduces maximum environmental damages. The idea of being sustainable is done by closing the loop and including the reuse, recycle step. This will aim at reducing environmental impact from the acquisition of raw materials to the final use and disposal of the product (Ali Esfahbodi, 2016).

Based on (Ali Esfahbodi, 2016), the main activities in a typical sustainable supply chain management (SSCM) are illustrated above. When the product has a defect after its production, it is sent back to the inventory to reuse or recycle it. When the product comes to its end, it goes to the plant where the product is reused, recycled, or refurbish before heading back to the supplier.

Four fundamental practices:

Understanding the way traditional vs e-business models impact sustainability is a vital step to the optimization of the supply chain. Based on (Ali Esfahbodi, 2016) research, Chinese and Iranian governments have focused their fight for GSCM based on four fundamental practices: sustainable procurement, sustainable production, sustainable distribution, accurate 3PL reporting, and reverse logistics.

These practices represent how each country engages itself toward Sustainable Supply Chain Management. In addition, these initiatives are not just used in China and Iran but also in many other emerging economies. These innovations represent a substantial commitment through strategic environmental plans toward sustainable Supply Chain Management.

Sustainable Procurement

consists of environmentally friendly purchasing that carries reduction, reuse, and recycling options. Furthermore, it is a solution to achieve a selection of products and services that reduce the negative impact of the life cycle.

Sustainable purchases become easier throughout the year with fewer barriers as customers increase their demands for environmentally friendly goods (Vishal Gupta, 2013). Ikea is a good example as it has sourced close to 50 percent of its wood from sustainable foresters and a hundred percent of its cotton from farms that meet better cotton standards (Ikea, n.d.).

Sustainable Production

Is the production process that uses inputs with low environmental impact, is greatly influential, and causes no waste pollution. Green production can improve the corporate image and lower the raw material cost.

Companies are starting to take action and produce materials that intend to be reliable, and energy-efficient with no or lesser waste. This benefits companies in many ways as it will impact customers, shareholders, and the company’s recognition in the e-commerce marketplace. (Vishal Gupta, 2013).

Sustainable Distribution

The distribution of goods usually generates a lot of waste and it can damage the environment, but green distribution consists of green packaging including size, shape, and materials that have an impact on the transportation of the goods.

Better packaging can reduce material usage, increase space utilization in the warehouse and trailer, and lower the quantity of handling required (Vishal Gupta, 2013). Logistrap does it in Mexico, they reduced their space within the warehouses and container ships to transport more within the same number of trips (Logistrap, 2020).

Reverse Logistics

According to (Vishal Gupta, 2013) the concept of Reverse Logistics (RL) means the returns from not only the customers but also the management of E-waste. RL is a process where a manufacturer accepts previously shipped products from the customer’s point of view for potential recycling and/or re-manufacturing.

Partnerships such as google warehouses and 3PL service providers can improve reverse logistics and keep the supply chain flowing smoothly with enhanced supply chain tools and tech. Backward integration and monitoring are necessary, especially during peak seasons when purchases, as well as returns, can be higher than normal.

Improve 3PLS Reports and Logistics Management With ModusLink

Do you need help figuring out how to become more sustainable within your management and logistics operations? Mastering the flow of 3PL reports, google warehouse management, and other supply chain management operations is a vital part of modern business operations today. Contact one of ModusLink’s leading supply chain management and logistics experts.

Bibliography:

12 Million Bottles Used in Patagonia Recycled Clothes. (1995, April 12). Los Angeles Times. Ali Esfahbodi, Y. Z. (2016). International journal of production economics (Vol. 181 part B). (S.Minner, Ed.) Birmingham , UK: Elsevier.

Avittathur, A. A. (2016). Green Retailing: A New Paradigm in Supply Chain Management.

Calcutta, India: IGI Global.

Bhattacharjee, K. (2015). Green Supply Chain Management- Challenges and Opportunities.

Research scholar, Patna University, Applied economics & Commerce, Patna. Cardwell, D. (2014, July 30).

At Patagonia, the bottom line includes the earth. The New York Times(section B), 1.

CHAPPELOW, J. (2016, March 16). Emerging market economy. Retrieved from Investopedia. consulting, T. E. (n.d.). reverse logistics in a circular economy. Retrieved from Triple EFF

consulting.

EM Ojo, C. M. (n.d.). GREEN SUPPLY CHAIN MANAGEMENT IN DEVELOPING COUNTRIES. In C.

M. EM Ojo. Johannesburg, South Africa : Department of Mechanical Engineering Science, University Of Johannesburg, Johannesburg, South Africa. Ikea. (n.d.). Corporate news. Retrieved from Ikea.com.

Kobo360. (n.d.). Kobo. Retrieved from Kobo360.com.

Logistrap. (2020). Logistrap packing services. Retrieved from Logistrap.com. 15

Mohsin Malik, S. A. (2019). Sustainability Initiatives in Emerging Economies: A Socio-Cultural Perspective . Swinburne University of Technology. / Abu Dhabi University., Department of Business Technology and Entrepreneurship / College of Business Administration. Abu Dhabi, UAE.: MDPI.

O. Zhu, J. S. (2005). Green supply chain management in china: pressures, practices and performance (Vol. 5).

Queiroz, M. M. (2019). Environmental Quality Management (Vol. 3). (Wiley, Ed.) Wiley.

Rama K. Jayanti, M. R. (2014). Sustainability dilemmas in emergingeconomies. (I. M. review, Ed.)

Bangalore, India: Elsevier Ltd.8).

Vishal Gupta, N. A. (2013, January). Green Supply Chain Management Initiatives by IT

Companies in India. The IUP Journal of Operation Management , 12(2), 6-24.